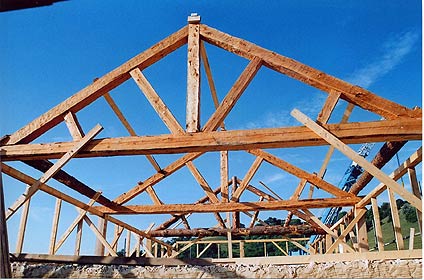

For centuries, home builders have used the web of wooden triangles joined at nodes by wooden straps known as trusses in the construction of roofs for homes.

Timber Roof Trusses (or Wood Trusses) are of course mostly made of wood that consists of a rafter and a tie beam.

Use of Wood Roof Trusses in Residential Structures

Wood or Timber roof trusses provide the structure and definition of the roofline of the house. Contractors continue to use the triangle as the basic form of wood trussesbecause it resists distortion when the length of the sides are fixed and joined to other triangles. The lumber used on stick built wood roof trusses is usually 2×6 inch beams and the average span of lightweight wood trusses is between 26-32 feet. Many homeowners choose to have trusses isntalled in their living room or great rooms and leave them exposed for a decorative touch and a more open feel.

It is possible to build Timber roof trusses with pretreated lumber to minimize the risk of insect and moisture damage. This wood truss design provides strength to the roof to prevent sagging and mitigate the risk of collapse. It is possible to engineer wood roof trusses in a variety of configurations providing architects and homeowners a multitude of wood truss design options.

It is possible to build Timber roof trusses with pretreated lumber to minimize the risk of insect and moisture damage. This wood truss design provides strength to the roof to prevent sagging and mitigate the risk of collapse. It is possible to engineer wood roof trusses in a variety of configurations providing architects and homeowners a multitude of wood truss design options.

Types of Wood Trusses

The most commonly used wood roof trusses are as follows: the King post truss, the W type wood roof truss, and the scissors truss.

King Post Timber Roof Trusses

The King post wood roof trusses are the simplest truss making it a good option for the do-it-yourself homebuilder. The King post wood truss design is constructed by joining two angled supports to a common vertical support. Although these type of wood roof trusses are easy to build, it is useful only for roofs with short spans. This type of frame can be made with braces and curve systems in order to create a more dramatic look.

W-Type Timber Roof Trusses

The W-type truss can be used in the construction of roofs involving spans of up to 50 feet. Although the W-type wood roof truss is more cost efficient as compared to other wood roof truss types, there is a tradeoff for less usable storage space in the attic area of the home. The construction of this type of wood roof truss is more complicated for the person building their own home due to the number of joints and angles involved in the construction. The individual who wants to build his or her own home can overcome this obstacle by ordering a pre-fabricated wooden roof truss from a reputable manufacturer located near the area of the structure. When the homeowner contracts the company to order a wood roof truss, he needs to have the following specifications available: the location of the structure, the span of the roof; the pitch of the roof, the planned spacing of the wood trusses and the roof load.

The W-type truss can be used in the construction of roofs involving spans of up to 50 feet. Although the W-type wood roof truss is more cost efficient as compared to other wood roof truss types, there is a tradeoff for less usable storage space in the attic area of the home. The construction of this type of wood roof truss is more complicated for the person building their own home due to the number of joints and angles involved in the construction. The individual who wants to build his or her own home can overcome this obstacle by ordering a pre-fabricated wooden roof truss from a reputable manufacturer located near the area of the structure. When the homeowner contracts the company to order a wood roof truss, he needs to have the following specifications available: the location of the structure, the span of the roof; the pitch of the roof, the planned spacing of the wood trusses and the roof load.

Scissors Type of Timber Roof Trusses

Builders of log cabins and homes with cathedral tend to favor the scissors type of Timber roof trusses. The trusses of Timber Roof Trusses allow for a cathedral style interior ceiling and the exposure of the beams for homes with a more rustic or natural appeal. Scissors wood truss designs are the most complex type of the wood roof truss to build so homebuilders tend to order these trusses pre-fabricated as the engineering of load distribution is more complex. These types of wood trusses do not allow for any attic storage but provides for dramatic interior design.

Tips for Choosing Timber Roof Trusses

There are three characteristics that need to be considered when choosing a timber roof truss. First, the timber should be lightweight, but strong. The timber will need to be kiln dried and strength graded. Next, the design of the roof truss is extremely important. It is critical not to make any changes to the truss without consulting an engineer as doing so can result in the roof collapsing. Finally, connection of the wood must be performed by an engineer as misplacing a screw, peg, or blot can decrease the strength.

There are three characteristics that need to be considered when choosing a timber roof truss. First, the timber should be lightweight, but strong. The timber will need to be kiln dried and strength graded. Next, the design of the roof truss is extremely important. It is critical not to make any changes to the truss without consulting an engineer as doing so can result in the roof collapsing. Finally, connection of the wood must be performed by an engineer as misplacing a screw, peg, or blot can decrease the strength.

Timber or wood roof trusses are reliable. However, things can go wrong with them. It is important to watch for things that could cause them to fail, such as exposure to dampness for long periods of time, which can result in loss of strength in the wood.